CERLOS

OUR MISSION

MOXY OID has developed the disruptive building material we have all been waiting for – one that saves time, money, and lives.

CERLOS was born through our desire to solve four global issues; agricultural/forestry waste, energy shortfall, hazardous building materials and environmentally unsustainable.

Not only do we repurpose agricultural or forestry waste, but it is environmentally friendly in both its manufacturing and application. CERLOS is available at a price point that is equal to or less than its competitive products. This proprietary, brand-new material will fundamentally change the trillion-dollar building materials industry.

FIRE DAMAGE

An estimated $23 billion in property damage occurred in the United States alone as a result of fire in 2017, this number includes a $10 billion loss in wildfires in Northern California. These fires resulted in 3,400 civilian fire fatalities, 14,670 civilian fire injuries. There was a civilian fire death every 2 hours and 34 minutes and a civilian fire injury every 36 minutes in 2017. A fire occurs in a structure at the rate of one every 63 seconds, and a home fire occurs every 88 seconds.

PESTS & INSECTS DAMAGE

Termites and rodents destroy most common building materials from structural beams to siding/cladding. U.S. annual pest control costs are approaching $10 billion per year, while world-wide the figure is far higher. In addition to the billion in costs attempting to prevent insect damage, the protection often relies on toxic chemicals that endanger children, other animals and ultimately, humanity.

MOLD & MILDEW DAMAGE

Wood and drywall can trap moisture and feed mold or mildew in our homes. Before a construction team completes a home, the wood often gets exposed to humidity, rain, freeze/thaw, sun, and even snow. Eventually mold damage can penetrate a home to the extent that walls and structural components must be torn out and replaced. Children and older adults are especially susceptible to respiratory diseases from mold exposure.

ENVIRONMENT & HEALTH DAMAGE

In addition to the death and destruction, available materials are damaging the environment. Many commonly used building materials contain toxins like cyanide while others contain silicas, known cancer causing agents. Numerous other building materials at the end of their life cycle are considered hazardous waste. Combined with the fact that these materials contribute to massive deforestation, we are creating more unusable waste while depleting resources.

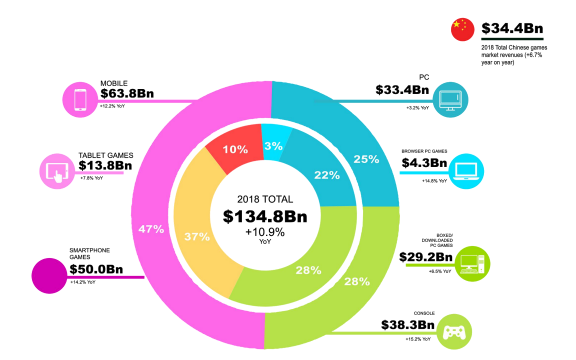

USA MARKET SIZE

GLOBAL MARKET SIZE

Why are we holding a token sale?

We have functioning prototypes. CERLOS works. High volume manufacturing process has been validated. Now we need to tell the world! The Token Sale will allow us to scale the CERLOS vision, through covering necessary manufacturing and marketing costs needed to fulfill orders.

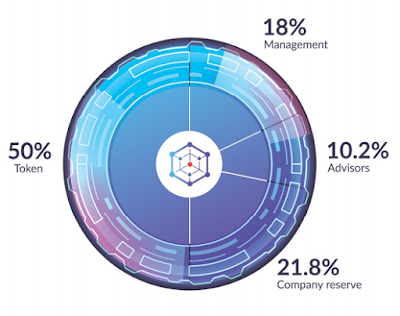

Unsold tokens will be retained by the Company as treasury tokens. Just like treasury shares they are not included in the distribution of dividends or the calculation of earnings per token. The Company, through a board resolution, may decide to offer them again for funding at a future date.

Who will qualify to invest?

Qualified investors must undergo a KYC process. Investors from the following countries are not allowed to participate: Malaysia, USA, Canada, Syria, Iran, Iraq, Congo, Libya, North Korea, Somalia, Sudan, Ukraine, Venezuela, Yemen, Zimbabwe, Belarus, Cuba.

Tokenomics

MINIMUM GOAL - $2,000,000

FUNDRAISING GOAL - $20,800,000

NOMINAL TOKEN PRICE - $1.00

JURISDICTION - Labuan - Malaysia

ASSET CLASS - Asset Backed Token

INVESTOR RIGHT - Profit participation right

ACCEPTED INVESTMENT CURRENCIES - Bitcoin, Ethereum, USD, Euro, GBP

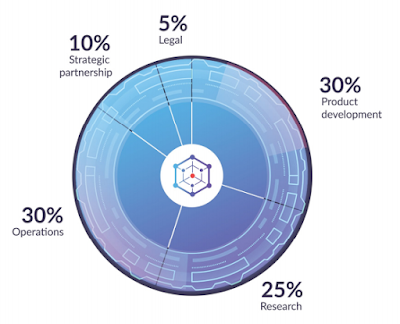

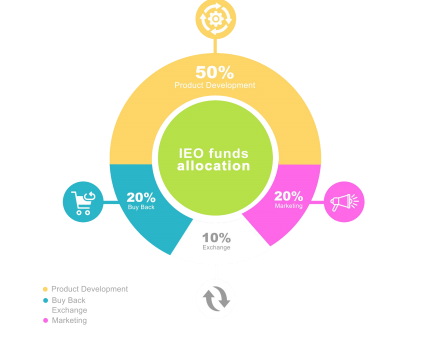

Use of Funds

Our Roadmap

1985

Alan Heywood (President & CTO) purchased a patent and formed C-Max Technologies International Inc.

1986-2002

Lab research and testing. The IP is developed. $12 million spent on R&D.

2002

C-Max Technologies is dissolved. Alan develops the technology as a sole proprietor.

2003-2008

Alan continues to research, focusing on sources of ingredients and process equipment. Engagement with Corvallis Tool Company of Oregan to design and manufacture a preliminary design. Further $1 Million is spent on R&D.

2010

MOXY OID is established to aid the management and commercialization of the technology. Cost: $2 Million.

2012-2017

Pilot Plant process facility is built in Holland by VDL Enabling Technologies group. High-volume production validated. $7 Million spent.

2018-2019

Preparation and development of websites and documents for funding of high-volume manufacturing facility and legal requirements. Cost is $500k.

March 2020

Pre-Sale Starts

First Quarter 2020

Begin High-Capacity design/build of manufacturing line

Second Quarter 2020

Canada/US Site Selection

Second Quarter 2021

First Employment of High-Capacity of 450 million ft2 per year in North America

Management Team

Robert Bedard

eMBA, Chief Executive Officer

Alan Heywood

President Chief Technology Officer/Inventor

Robert Gagné

CIPM, CISM, CISSP, CRISC, Chief Information Officer

Mark Soloman

VP, Business Development and Marketing

Antoon Eggenhuizen

European Advisor

Advisor

Don Asok

Technology Advisor

Vin Menon

Blockchain Advisor

Kate Alippa

Marketing Advisor

Information

Author